Ministry of Science and

Higher Education

of the Russian Federation

Russian Academy of Sciences

Department of power engineering, mechanical engineering, mechanics and control processes

for english » Research Departments » Department of Friction, Wear and Lubrication. Tribology » Main Research Results and Achievements » Magnetically controlled lubricants (MSM) with nano-sized ferro-phase and increased thermostability

Magnetically Controlled Lubricants (MSM) with Nano-Sized Ferro-Phase and Increased Thermal Stability

- The scientific fundamentals for increasing the orientation ability of the friction surface in the presence of thin diamond-like coatings have been developed. A computer model is developed for a boundary lubricating layer formed on surfaces having orienting properties (it is a collaborative development of the Laboratory of Investigation of Wear at Boundary Lubrication of the IMASH RAN together with the Chemical Department of M.Lomonosov Moscow State University (KhimFak of the MGU).

- The Sakhalin-2 Project is estimated to be the largest integrated oil and gas project ever undertaken in the world. Unprecedented for the petroleum industry is also the use of mobile supports in the connections between the base and the upper structures of the oil platform. The device (seismic insulators) helps to withstand the strongest earthquake - during the underground shakes, the movable supports allow the elements of the structure to swing gently from side to side, protecting them from destruction. Simultaneously, the supports compensate for wave, ice and temperature loads on the equipment of the upper structure. The central support element is a thin anti-friction composite gasket (~ 3: 5 mm), on the condition of which depends the operability of the entire device, calculated for the service lifetime of 30 years.

- An experimentally calculated methodology for service lifetime determining has been developed (using the dependence to determine the wear rate presented in the generalized variables) and the friction coefficients of cylindrical and spherical dry friction sliding bearings operating under a swing and reverse motion. Comparison between the results obtained by the developed methodology and experimental results, which showed satisfactory agreement, is conducted. The proposed formulas can be used for calculations at the stage of designing tribo-conjugates. Based on the solution of the thermal contact problem, a method is proposed for determining the temperature distribution law inside of a sliding bearing (seismic isolator). The results of the conducted experiments confirmed the correctness of the theoretical estimates of the sevice life of the pendulum bearings, which previously made possible to predict correctly their reliable operation during the entire lifetime of 30 years. The research project was carried out jointly with the Laboratory of Friction Units for Extreme Conditions of the IMASH RAN. Financial support was obtained by the grant of the Russian Basic Research Foundation (the RFFI) for 2007-2009 No. 06 - 08 - 00363a). The Project Leader was Prof., Sc.D.(Engineering) Yu.N.Drozdov.

- The pilot-industrial technology for the mechanical processing of ChSTs crystals for tribotechnical parts has been developed and experimental batches of parts made of the ChSTs crystals and ceramics have been manufactured, such as: bearing bushings for operation under extreme operating conditions; dies for the calibration of wire of various sizes; medical products: surgical scalpels, dental implants.

|

|

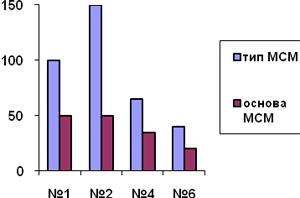

| Фаза №1 | Ресурс (минуты) МСМ при 150 С0 |

|

|

|

| Фаза №2 | Ресурс (минуты) МСМ при 200 С0 |

|

|

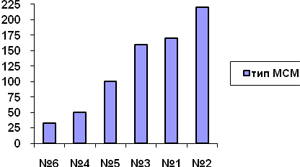

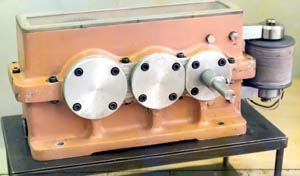

| Фаза №3 | Цилиндрический редуктор |

|

|

| Червячный редуктор |